Process issues in AD can be detrimental. Problems in the digester can be the difference between profit and loss. This means that keeping your process out of trouble and running as effectively as possible is essential.

What Are AD Process Issues?

Process issues are when the variables that make up the anaerobic digestion process become out of balance with how the system was designed. This imbalance can then start to cause the digester to react in certain ways. These include scenarios such as foaming and souring. In some cases, the digester can become explosive, although this is extremely rare.

What Are the Main Causes of AD Process Issues?

Given the number of variables in the AD process, there are so many factors that can play a part in process issues. Some of the main variables include:

The Effects of AD Process Issues

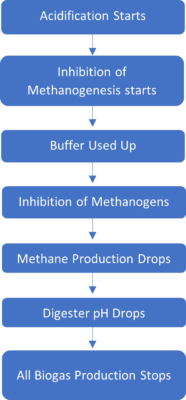

Process issues can be extremely expensive. Not only can it damage profits when poor amounts of biogas are produced, but it can also be expensive when you have to stop the process and empty the digester if it has soured. Every minute of downtime is costly to a process that commonly relies on continuous operation.

The process can become more odorous once the digester has started to perform poorly. With the imbalance in VFA’s and an increase in Hydrogen Sulphide, the smell can rapidly become unpleasant.

Process issues can also have damaging consequences on the other equipment in the process. Hardware such as pumps, macerators, valves even pipework can become damaged due to the process being unstable. This is because the content can erode and wear parts much quicker. In some cases, pressure increases can cause valves to blow.

Process issues can also cause damage to the environment. This is partly because of the incomplete digestion in the digester and therefore the digestate may still contain harmful elements that it wouldn’t have if the digester had gone through its complete cycle. The other part of this is that process issues can cause pollutants to be given off into the atmosphere due to digester emptying or leaking from a specific part of the process.

How Can We Avoid AD Process Issues?

As detrimental as process issues can be, many can be avoided by adopting good operational practices and being consistent with how you operate and monitor the system. This coupled with sufficient operator training can remove many problems with the process.

Feeding the digester at regular intervals can greatly improve the stabilization of the process. If the process is designed for a continuous flow then this will aid with consistency. It is then down to the process owner to ensure the feedstock is a consistent mix and the organic loading rate is kept consistent.

If the feedstock is to be altered at all in any way then these changes should be done gradually to allow the digester to not become stressed by the sudden change in biology. The same can also be said for the temperature in the digester. If the temperature has dropped then it is important to not increase it rapidly. This increases the chance of shocking the digester. It is better to increase the temperature as slowly as possible.

Ensuring the digester is being adequately mixed is another important part of the prevention of process issues. When the process is designed and commissioned this will be a main focal point. Considering the flow of feedstock, its contents and how often it is running will be some of the main factors when considering a mixing system.

Continuously monitoring the process and taking data samples to compare against the benchmark data is one of the most essential steps in avoiding process issues. The process needs to be monitored and measured daily. This ensures that any part of the process that may be operating inefficiently can be spotted early, and a solution can be created. If the process is not being measured frequently then it can often be too late to reverse the problem.

Reference – Roots Organics Ltd.