What Is Sludge Thickening?

Sludge thickening occurs when the liquids are removed from the sludge. This reduces the total sludge volume but the number of total solids that are suspended in the sludge is increased, often by 2-5x the amount. Depending on how much of the water is removed, the process is referred to as thickening or dewatering.

How Is Sludge Thickening Done?

There are 5 main methods of sludge thickening:

- Gravity thickening

- Centrifugal thickening

- Flotation thickening

- Gravity belt

- Rotary drum

Gravity Thickening

Gravity thickening is done by using a tank or vessel that contains the sludge. Once the sludge enters the tank the heavier particles then sink to the bottom and the liquid stays at the top. There is a scraper that rotates at the bottom of the tank to allow the solids to stay in suspension. The sludge is then pumped out from the bottom of the tank with the liquid or effluent being pumped from the top of the tank to be further processed.

Credit: eddypump.com

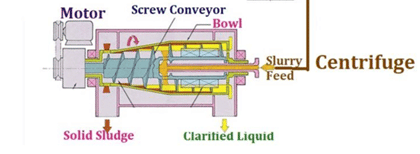

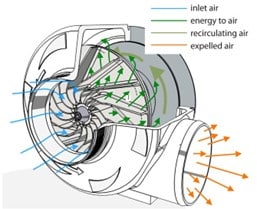

Centrifugal Thickening

Centrifugal thickening works by introducing a centrifugal force upon the sludge. This actively encourages the heavy solids to move outwards, and the liquid effluent will be removed conveniently.

Centrifugal techniques can be used in thickening and dewatering applications. However, there are some differences in the way they operate. These include:

- Rotational speed

- Throughput

- Solids contents percentage of the product generated

When dewatering is wanted to be achieved the outcome will be a dry cake that can’t be moved by the use of pumping systems. Whereas thickened sludge will still be able to be pumped where needed.

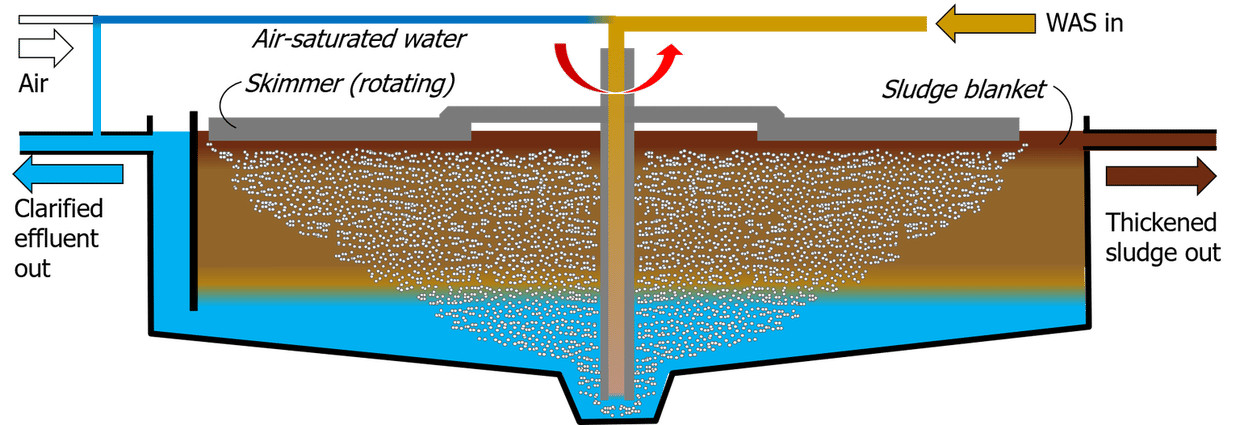

Flotation Thickening

Flotation thickening is commonly referred to as dissolved air flotation (DAF). DAF works by injecting air into the water to reach saturation. This is then pumped at high pressure into waste-activated sludge. As the sludge then enters the vessel the solids float to the top and are removed and the effluent is removed from the bottom of the tank to be further treated.

Credit: Judd Water & Wastewater Consultants

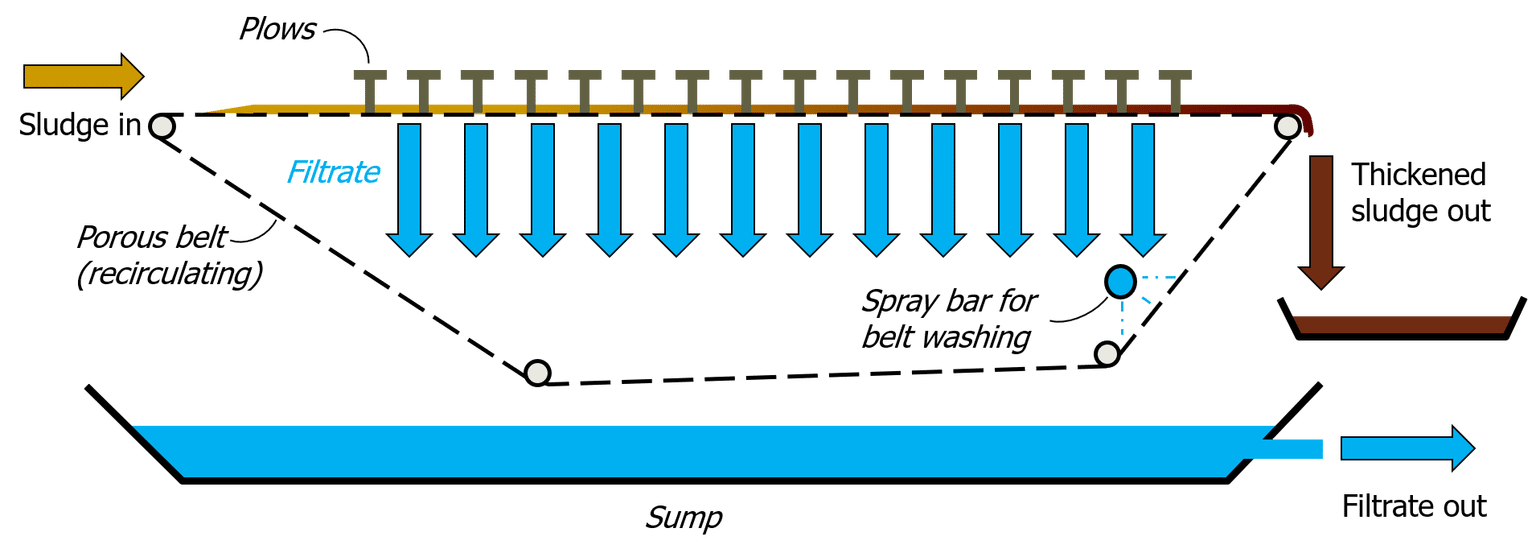

Gravity Belt

Gravity belt thickening uses the same principle as gravity thickening, hence the name. However, a rotating belt is introduced into this method. The belt itself is porous which allows the excess water to pass through leaving the sludge sitting on the belt, which is then moved along by the felt and eventually drops off into the next part of the process. The excess water that has fallen through the belt drops into a sump and is then transferred for further treatment.

Credit: Judd Water & Wastewater Consultants

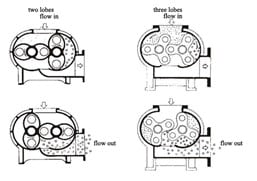

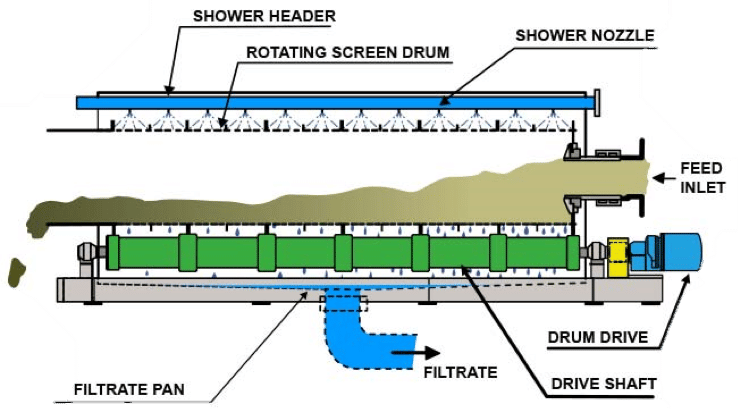

Rotary Drum

Rotary drum thickening works similarly to gravity belt thickening. A rotary drum uses a drum typically of 0.5-1.5m in length that is porous. Sludge is passed through the drum and the excess water falls through the holes in the drum into a sump to be further treated. The sludge continues to stay in the drum moving along continually until it reaches the end where it is then moved for further processing.

Credit: VIRIDIS Engineering

What are the Benefits?

There are multiple benefits to the sludge thickening process. One of the main benefits is that sludge volume reduction brings down capital costs to treat high volumes of sludge and the further treatment steps that are needed. Sludge thickening is also beneficial from a process stability standpoint because of the reduction in mass of the sludge which means there are fewer heating requirements, smaller tank sizes needed, and less external input required.

Reference – Sludgeprocessing.com