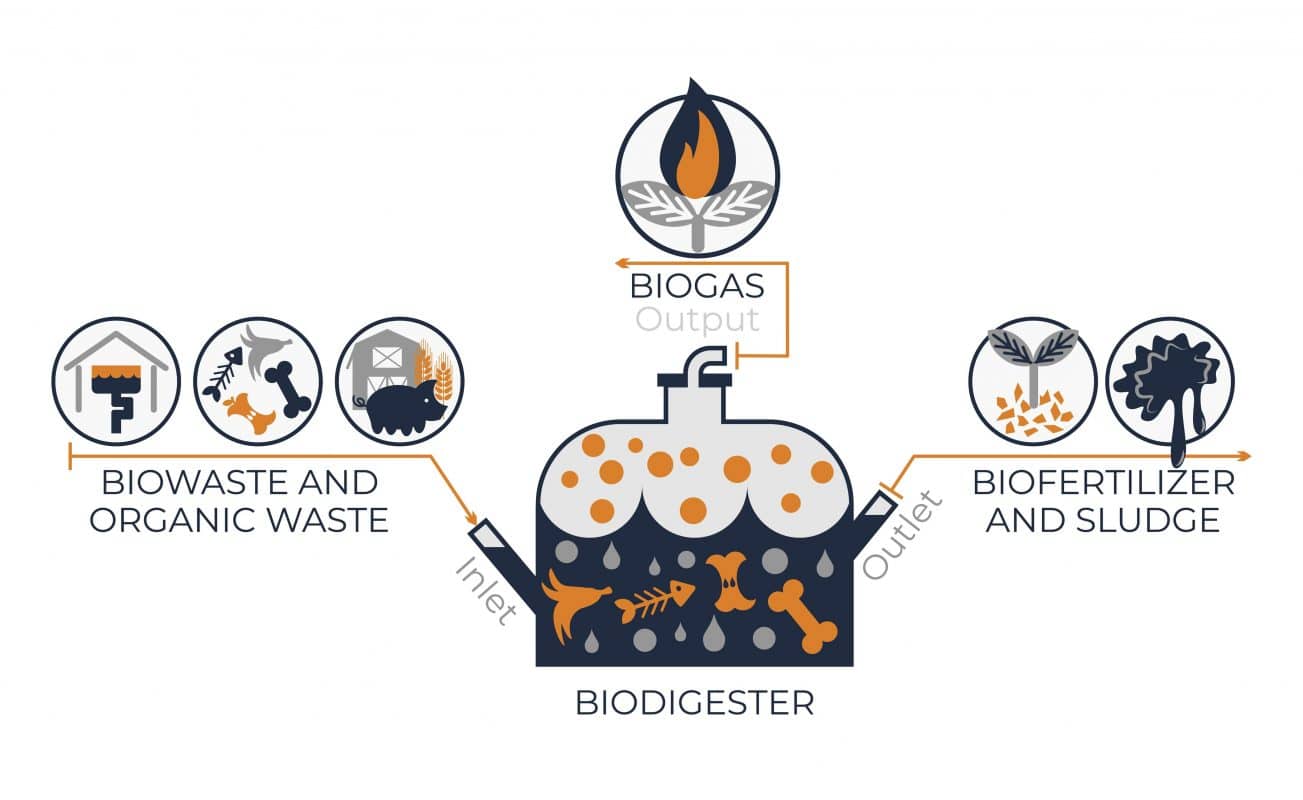

Once the feedstock has been digested in the digester we then get a residual. This residual is called digestate. The end product can be extremely good quality and useful for farmers to either pack and sell or spread it on their land. Spreading it on their land then means that it helps the crops grow. These crops are then either harvested and potentially put into the digester or are eaten by livestock whose waste feeds the digester. This makes it a circular economy.

What is Digestate?

Digestate is a residual outcome from the process of Anaerobic Digestion. It is extremely rich in nutrients and therefore a great fertiliser. The main nutrients in digestate are Nitrogen, Phosphorous and Potassium.

Different Types of Digestate

There are 3 common types of digestate:

Whole digestate – looks similar to livestock slurry and typically has less than 5% percent solids content

Liquid digestate – this is similar to whole digestate; however, the solids contents have been removed.

Fibre digestate – this is a compost like substance. Fibre digestate is the solids that were removed from the whole digestate.

Where Can It Be Used?

There can be many different uses for all types of digestate. Because the digestate has had the majority of toxins removed it makes for extremely good fertiliser. Liquid fertiliser is commonly spread on land to help crops grow. Fibre digestate can also be used as a compost/soil for personal use or it can be packaged and sold.

Regulations for Digestate

If the digestate is not to be considered as waste then it must meet the standards of the quality protocol and PAS110. These two standard ensure that the digestate that is being sold is fit for purpose and is non-toxic. These are two of the pillars that make up the biofertiliser scheme.

More on the benefits of Digestate