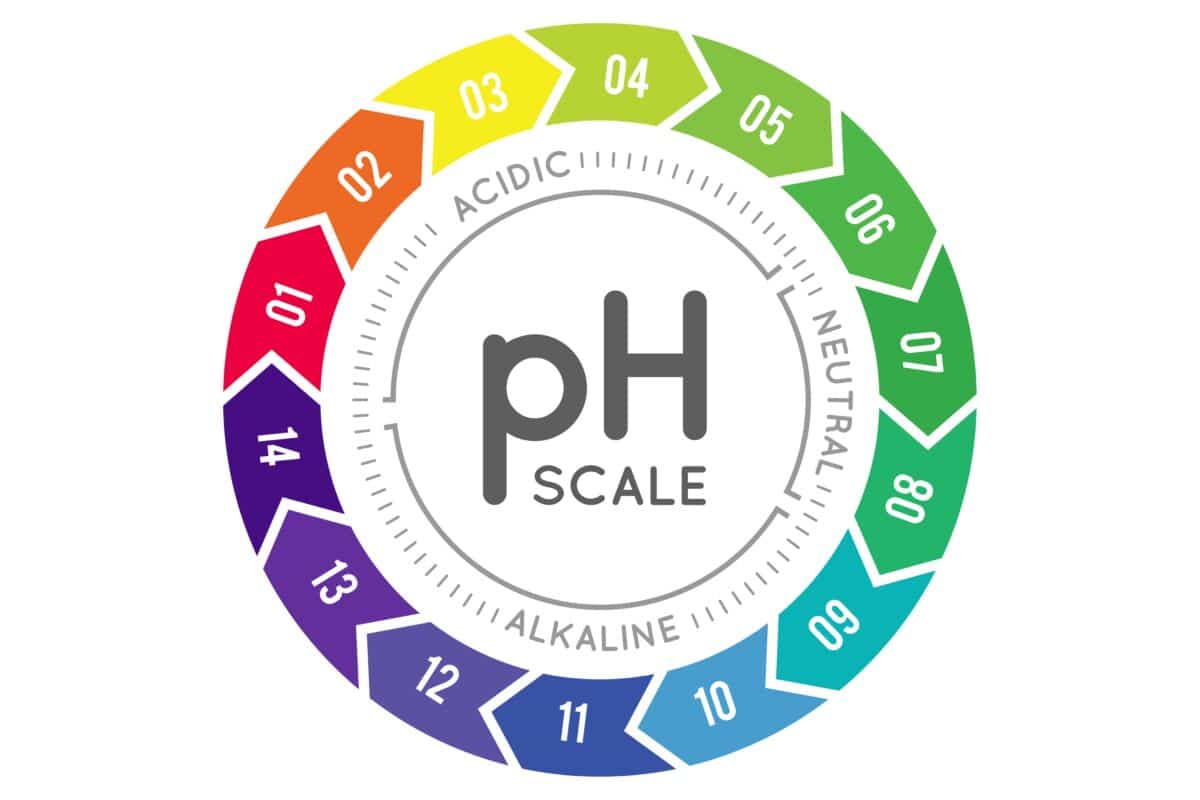

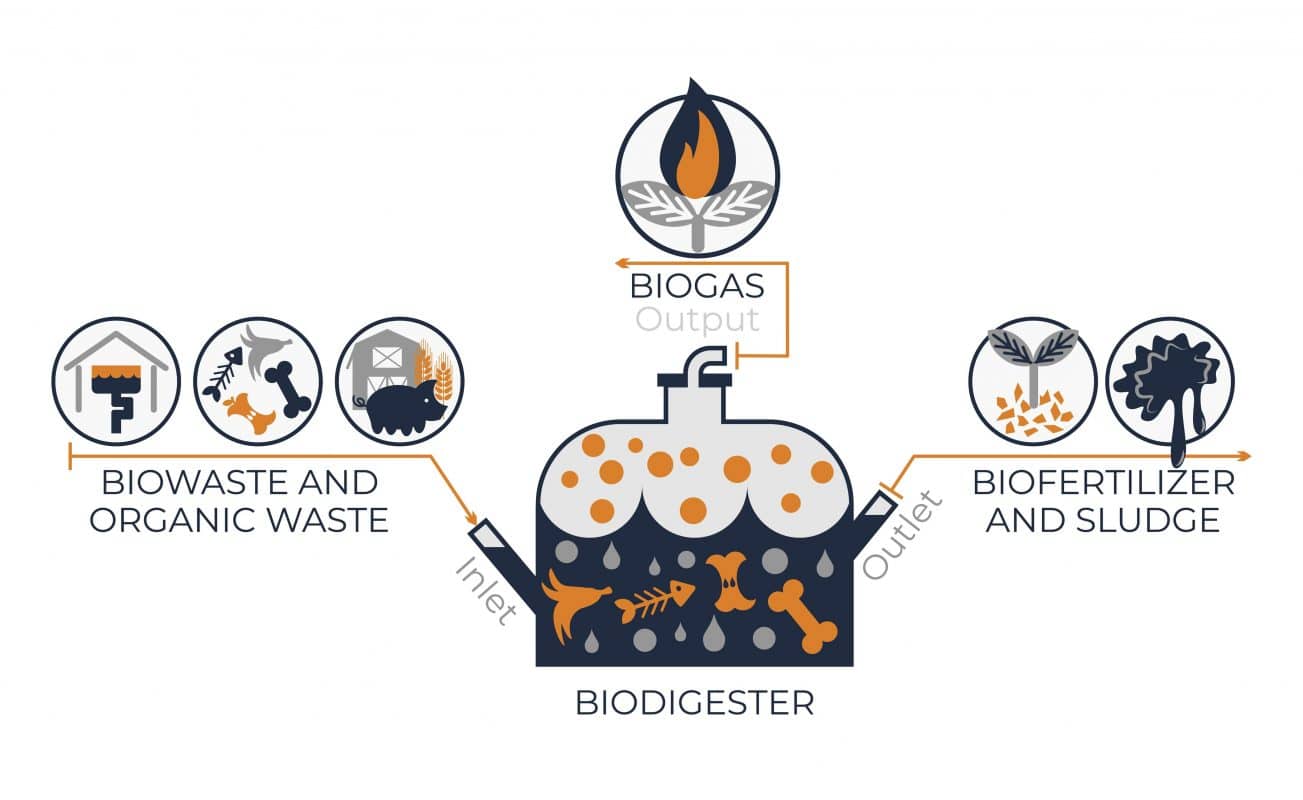

The pH balance in the anaerobic digestion process is critical. If the pH level is unstable, it can lead to underwhelming biogas yields, and often leads to odour from the process. There is a sweet spot for the pH levels to enable sufficient yield.

In an experiment conducted on grass silage and its biogas yield, dependent on process variables, it showed there is desirable combinations in the systems. These optimum points are largely down to the temperature and pH levels in the digester.

A mesophilic process normally sees the temperature set between 30-38˚c. In this experiment in particular the temperature was set at 35˚c. The pH levels were tested at 3 different levels. These were: 6.5, 6.8 & 7.2

The established, best combination for a mesophilic process was a pH of 6.8 at 35˚c. This combination saw a biogas yield of over 60%.

Multiple pH levels and temperatures were then trialed to find the best overall yield. The highest yield from the experiment as a whole, was achieved from having a temperature of 45˚c, at a pH of 6.5. It is thought that the reason for this is that the pH levels and temperature allowed for rapid growth of the bacteria that produce the biogas.

Continuous monitoring of the pH level in the digester is essential. It can be the difference between producing high amounts of biogas or unsatisfactory amounts. Less gas produced, equates to a less profitable process.