Digester souring can be one of the most detrimental outcomes in the process of Anaerobic Digestion. Every operator or process owner knows that this is the worst thing that can happen to the process and is one of the hardest to recover from. It often results in having to empty the digester and go through the start-up process all over again.

What Is Digester Souring?

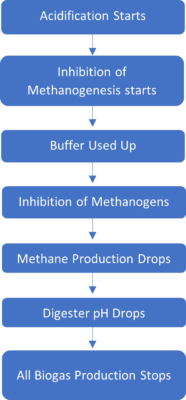

Digester souring is when one of the many variables starts to play havoc with the biological makeup of the contents inside the digester. The biological contents then start the acidification process, which in turn starts to inhibit methane production. Because of the acidification, the process is relying on the buffer (FOS/TAC & Buffers) to prevent the digester from souring. Unfortunately, when the buffer is then used, and the methanogens continue to be inhibited then methane production drops. This then drops the pH of the digester, causing it to sour. Any biogas production is stopped below a pH of 6.5

What Are The Main Causes of Digester Souring?

As always in Anaerobic Digestion there are so many variables that can affect how the process operates and the amount of biogas that is produced by the system. However, the most common culprits can be broken down into 4 steps:

- High OLR – Overfeeding the digester and stressing the biology

- Low retention time – Not calculating the correct retention time for the medium to be properly broken down

- Incorrect commissioning – Not setting up the plant to be effective

- Irregular feeding – Feeding the plant too often causes peaks and troughs in variables

How Can We Avoid Digester Souring?

Digester souring can be avoided by implementing a few changes and creating routines within the process.

To solve the OLR problem we can identify the optimum feeding loads into the digester. This can be done through the calculation to a certain extent and then trial and error to get the best results. The best way to overcome digester overloading is routinely feed the digester with the correct amount of feedstock that it has been designed to deal with.

This coincides with the feeding regime. It is vital to feed the digester periodically to allow it to operate as efficiently as possible. If we introduce irregular feeds we then start to have the variables of the digester rapidly changing, which then causes instability in the digester.

Another prevention method is establishing benchmark data from when the digester is performing at its best and then comparing it to the results on a daily or weekly basis. Being able to compare this data is invaluable for optimising performance and preventing digester souring. It allows the operator to spot any anomalies and deal with them before they become a problem.

Reference – Roots Organics Ltd