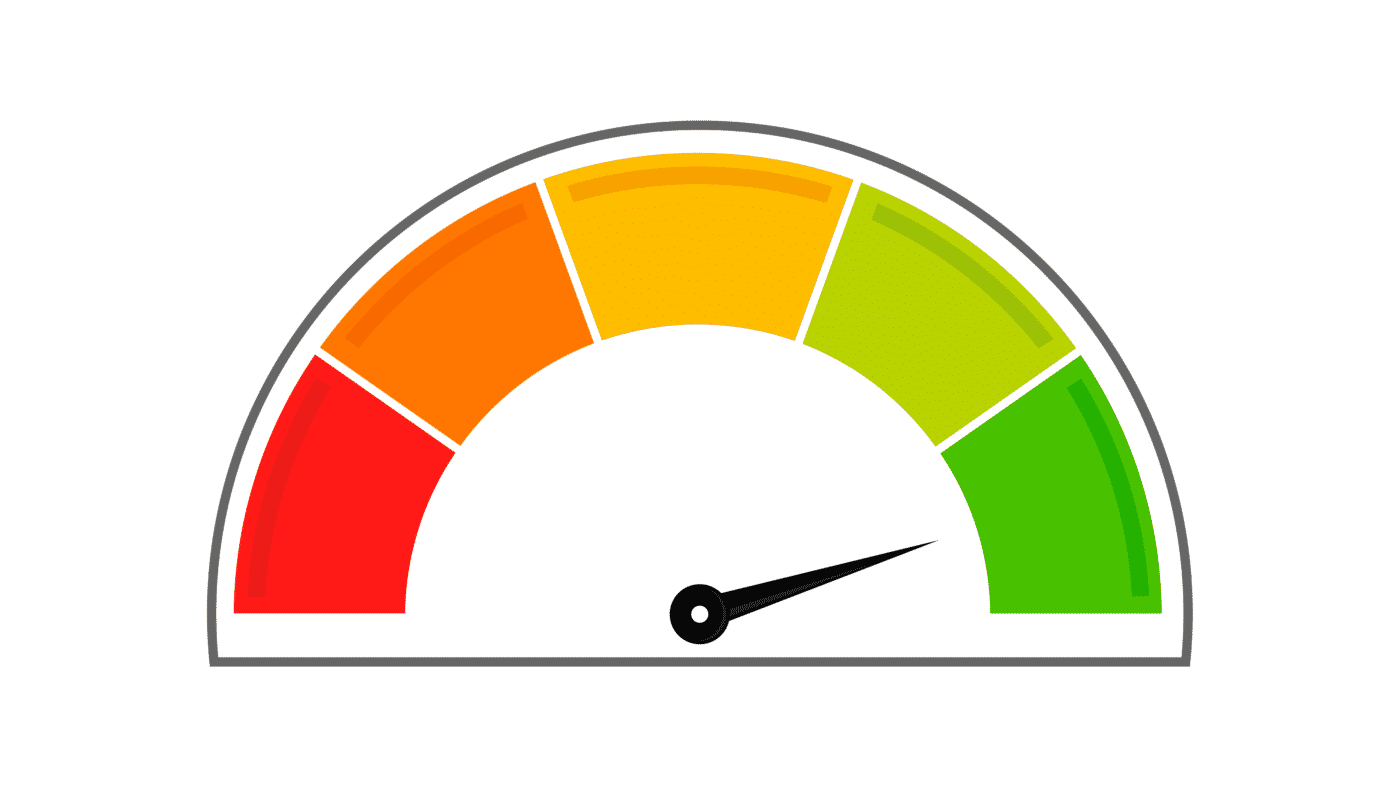

There are many indicators within a biogas system that can determine how well the system is operating. It can be an immediate response from the system or over a long period. Due to the process being made up of many variables it can often be difficult to locate the specific problem. However, from the response in the digester, we can then assess the actions needed.

Short Term

Biogas Quality

The immediate indicator from the digester will be the methane and hydrogen sulphide levels. In a normal digester, running efficiently, the methane levels will be expected to be around 75%, with carbon dioxide being a large proportion of the rest. If this percentage has dropped it may be cause for concern. Foaming and other process issues could be interfering with the production of quality biogas.

Biogas Volumes & Energy Yield

Much like the biogas quality, the volume will also be affected by inefficiency or a problem in the digester. This coincides with having benchmark data for your process. If there is a set standard of biogas you expect to see from the process per day and this is not being reached, then it requires further analysis. This then translates into the amount of energy yield. With the digester being inefficient and producing an inadequate amount of biogas, then the energy output from the system will be considerably less.

Medium Term

VFA’s, FOS/TAC & pH

Medium-term effects on the digester occur when particular levels in the process start to become abnormal. Telltale signs are the VFA (volatile fatty acid) profiles, the pH within the digester and the FOS/TAC levels.

Floating Layers & Foaming

Once the imbalance begins in the digester, it is followed by layers beginning to form on the surface of the digester. These can either be in the form of a ‘crust’ or foaming, depending on the imbalances. To counteract the layers forming, a good method of mixing is essential to keep the liquid moving. Also, clearing or breaking the layer can be useful to ensure the biogas can escape. Following this, it is essential to measure and monitor the levels in the system and compare them to the benchmark data.

Long Term

Digestate quality

The long-term indicator of a healthy system is the quality of the digestate. Once the digestate has been pumped out of the digester and de-watered, we can then assess its quality. These assessments are done primarily on the smell of the digestate, texture and also a visual inspection.