In the Anaerobic Digestion process biogas is produced which needs to be transferred from one place to another. The transfer of gas can be to the flare if it is excess gas, directly into a CHP unit or the national gird. This article explains how biogas can be moved from one part of the process to another.

What Are Biogas Blowers?

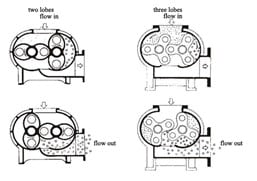

Gas blowers are often rotary, positive displacement machines that are used for the transportation of gases. Commonly, they are two or three lobe rotors. However, there are also centrifugal type blowers on the market. Biogas blowers can be used to supply, drive or extract biogas wherever needed in the process.

How Do They Work?

Positive displacement blowers have lobes inside that do not touch, meaning the gas is oil free. They rotate within the housing causing a pressure flow scenario. This means that the pressure varies to meet the systems requirements.

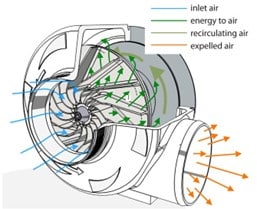

Centrifugal single stage blowers are constructed with spark proof aluminum casing and impellers. They do not require lubrication. Multi-stage blowers suck the gas into the inlet volute, from there every stage is linked to the first stage through a return channel. The main advantages of centrifugal type blowers are they are easy to install, low noise, minimal maintenance and no contamination.

References –

Centrifugal Type Gas Blowers (ggepower.com)

Process Gas Rotary Blowers in Process Industry | HIBON