What is Process Optimisation?

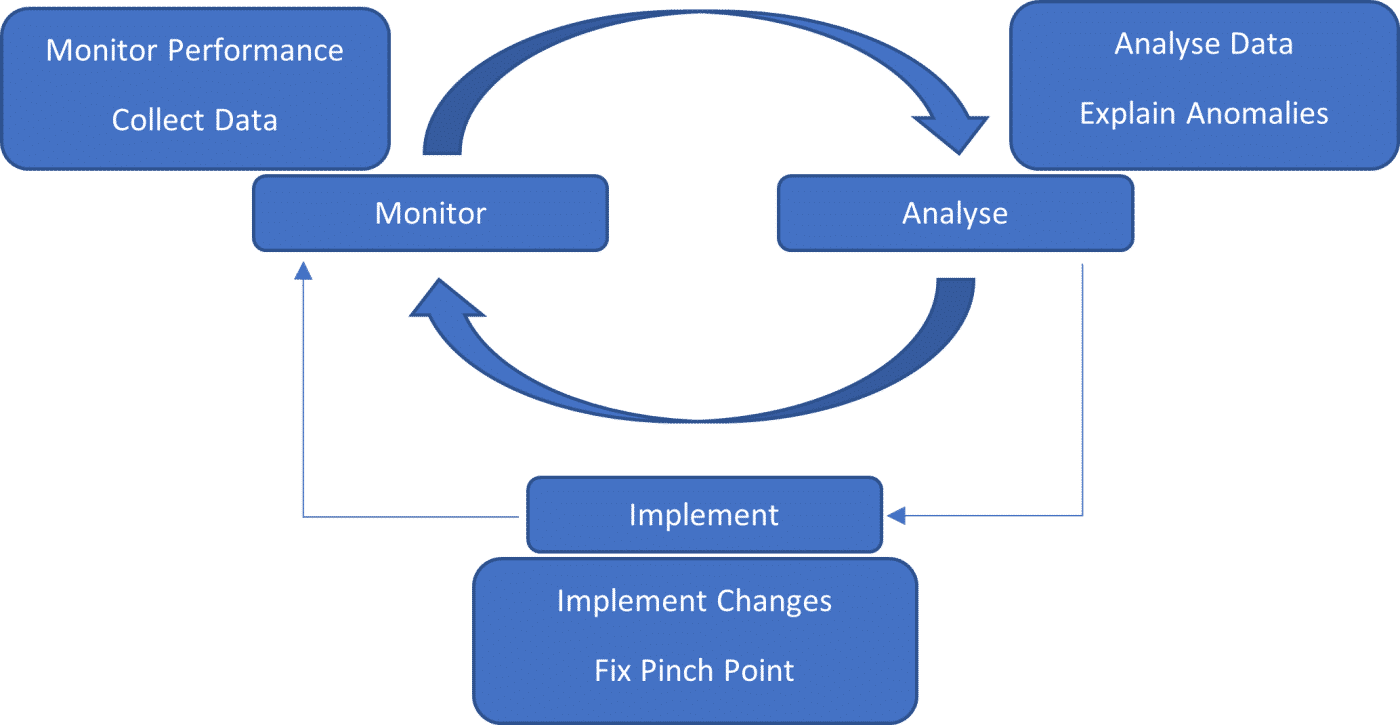

In any industry, professionals seek to optimise the way they do things, in search of achieving more. This is a measured process, which can be defined by a particular increase in a given metric, via a feedback loop. Anaerobic digestion is absolutely no different. In fact, the whole process of anaerobic digestion relies on process optimisation, as it is driven by the output of the process being as maximised as it can possibly be.

How to Optimise Your Process

It is possible to optimise your process through small, yet systematic adjustments to the process to make the most effective use of the parameters, whilst ensuring process critical constraints are adhered to.

First, the key objectives must be identified. Often these are to minimise cost and increase throughput in the system. They can also be to increase the overall efficiency of the digester. Once this has been done, the pinch points in the system can then be determined, and a necessary action plan can be made to ease that particular pinch point.

The aim at this stage is to focus on one key specification, whilst keeping the rest of the process within the constraints. Process optimisation is largely done through trial and error. Once the process has started to return a better output, another inefficiency can be addressed. Due to the small, yet systematic changes, if the change has a negative effect on the digester it is much easier to reverse than making a large change all at once.

Reference – Roots Organics Ltd